Understanding the Oil Pressure Sensor: How It Works, Why It Matters, and How to Maintain It

Learn everything about the oil pressure sensor — how it works, signs of failure, maintenance tips, replacement advice, and why it’s essential for engine health and performance.

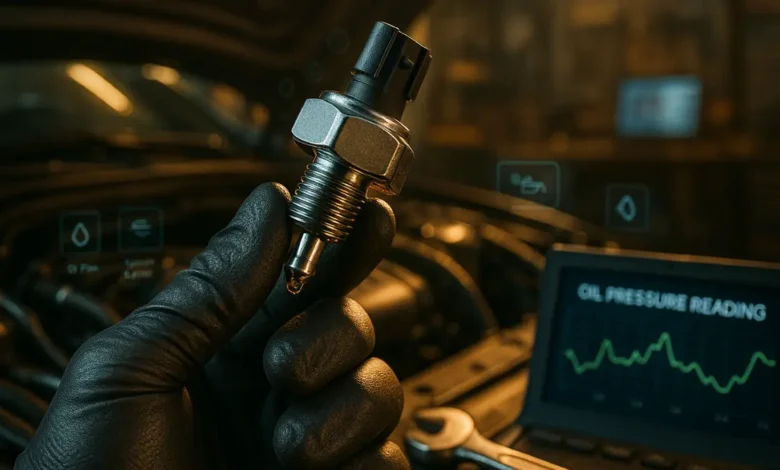

Oil Pressure Sensor Overview

The oil pressure sensor is one of the most vital yet underrated components of any modern engine. While most drivers focus on the big, noticeable parts like the engine, battery, or tires, the oil pressure sensor quietly ensures that your engine’s lifeblood — the oil — is flowing properly. It acts as the system’s watchdog, constantly monitoring oil levels and pressure to alert the driver if something’s off.

An oil pressure sensor isn’t just about warning lights or dashboard alerts; it’s about protecting your engine from catastrophic damage. If the oil pressure drops too low, your vehicle’s engine could overheat, seize, or wear out prematurely. Understanding how this small sensor works and recognizing the signs of failure can save you from expensive repairs down the road.

How an Oil Pressure Sensor Works

At its core, the oil pressure sensor functions as a monitor for the engine’s lubrication system. It measures the force of oil circulating through the engine and sends a signal to the car’s computer or dashboard gauge. This feedback tells the system whether the oil pressure is at a safe, optimal level.

Inside the oil pressure sensor is a small diaphragm that reacts to oil pressure. As oil moves through the engine, it exerts pressure on this diaphragm, which in turn creates an electrical signal proportional to the pressure. The vehicle’s onboard computer reads this signal and translates it into information — either showing you a pressure reading on your gauge or activating a warning light if levels drop too low.

It’s a simple yet incredibly effective design. Without it, you’d be driving blind, unaware that your engine might be suffering from low oil pressure — something that could quickly lead to irreversible damage.

Importance of an Oil Pressure Sensor in Engine Health

The oil pressure sensor acts as an early warning system for your vehicle’s engine. Its main purpose is to alert you before the damage happens. Oil pressure is crucial because it ensures all moving parts of the engine are lubricated. Without proper lubrication, metal parts grind against each other, leading to wear and overheating.

A failing oil pressure sensor can lead to misinformation — it might show that your oil pressure is fine when it’s dangerously low, or it could display constant false alarms. Either situation can cause confusion and lead to neglect. When your oil pressure sensor works correctly, it gives you peace of mind that your engine is running smoothly and safely.

In modern vehicles, this sensor also plays a role in advanced diagnostics. It can communicate with the engine control unit (ECU), helping the system make automatic adjustments if necessary, such as activating fail-safe modes or adjusting performance parameters.

Signs of a Faulty Oil Pressure Sensor

Just like any other component, the oil pressure sensor can wear out over time. Recognizing the symptoms of a bad oil pressure sensor is essential for early maintenance. One of the most common signs is an inaccurate or flickering oil pressure gauge. If your dashboard oil light turns on and off erratically, it could indicate a malfunctioning sensor rather than an actual drop in pressure.

Another symptom is when the oil pressure warning light stays on even though your oil levels and quality are fine. Conversely, a bad sensor might fail to warn you when oil pressure truly is low — a dangerous situation that can lead to engine damage. Some drivers also notice poor engine performance or strange noises, especially if the faulty sensor leads to incorrect ECU readings.

Ignoring these warning signs is risky. Even if it turns out to be just the sensor, it’s better to address the issue early rather than assume it’s harmless.

Common Causes of Oil Pressure Sensor Failure

There are several reasons why an oil pressure sensor might fail. The most common cause is oil contamination. Over time, oil can carry small particles, sludge, or debris that clog or damage the sensor’s diaphragm. Electrical issues are another culprit; damaged wiring or corroded connectors can disrupt the signal from the sensor to the dashboard.

Extreme heat and vibration also take their toll. Engines operate in harsh environments where temperature fluctuations and mechanical stress are constant. These conditions can wear down the sensor’s internal components, reducing accuracy or causing total failure.

In some cases, the problem isn’t with the sensor itself but with the oil pump or oil filter. A failing pump can cause actual low pressure, which makes the sensor appear faulty. That’s why proper diagnosis is key before jumping to conclusions.

Diagnosing Oil Pressure Sensor Problems

If you suspect your oil pressure sensor is acting up, there are a few steps you can take to diagnose it. Start with a visual inspection — check for oil leaks around the sensor’s housing. Oil leakage can indicate a cracked or worn sensor body. Next, inspect the wiring and connectors for corrosion, fraying, or disconnection.

The next step involves using a mechanical oil pressure gauge. By temporarily replacing the electronic sensor with this tool, you can compare the readings. If the mechanical gauge shows normal pressure while your car’s dashboard indicates a problem, your oil pressure sensor is likely to blame.

Mechanics often use diagnostic scanners to read trouble codes from the ECU. Many vehicles will store fault codes related to oil pressure if the sensor is malfunctioning. Combining these diagnostic methods ensures accurate identification of the problem before you replace any parts.

Replacing an Oil Pressure Sensor

Replacing an oil pressure sensor is a relatively straightforward process for most vehicles, but it requires care and precision. The first step is to locate the sensor, usually near the oil filter or on the engine block. Once you disconnect the electrical connector, you can unscrew the old sensor using the appropriate socket or wrench.

Before installing the new sensor, it’s important to clean the surrounding area to prevent contaminants from entering the engine. A bit of thread sealant can be applied to the new sensor to prevent oil leaks. After tightening it into place, reconnect the electrical connector and start the engine. Check the dashboard to ensure the warning light has turned off and the pressure reading is accurate.

While it’s a simple job for those comfortable with tools, anyone unsure should let a professional handle the replacement. The cost of a new oil pressure sensor is much less than repairing an engine damaged by incorrect installation or neglect.

Maintenance Tips for Prolonging Sensor Life

Routine maintenance is the key to keeping your oil pressure sensor in good condition. Regular oil changes are essential because dirty or old oil can cause buildup that clogs the sensor. Always use the recommended oil type for your vehicle to ensure consistent performance and reduce the risk of residue formation.

Inspecting the sensor during oil changes is a smart habit. Look for leaks, corrosion, or loose connections. Keeping the surrounding area clean and dry can extend the lifespan of the sensor significantly. Avoid over-tightening the sensor during installation, as it can damage the housing or threads.

If your vehicle frequently experiences extreme temperature shifts or heavy-duty driving conditions, it’s even more important to check the sensor periodically. Preventive attention now can prevent costly repairs later.

The Relationship Between Oil Pressure and Engine Performance

Oil pressure plays a direct role in how efficiently and safely your engine operates. When the oil pressure sensor detects proper flow, it ensures that every moving part — from pistons to camshafts — gets the lubrication it needs. This minimizes friction, reduces heat buildup, and helps maintain performance.

Low oil pressure, on the other hand, can cause a chain reaction of problems. The lack of lubrication leads to friction, which in turn causes heat and metal wear. Over time, this can reduce power output and fuel efficiency. By keeping tabs on your oil pressure sensor, you’re effectively monitoring the health of your entire engine system.

A well-maintained sensor ensures that even the smallest fluctuations in oil pressure are detected early. This makes it one of the most valuable components for maintaining long-term performance and reliability.

Comparing Oil Pressure Sensors: Mechanical vs. Electronic

Oil pressure sensors come in two main types — mechanical and electronic. Mechanical sensors have been around for decades and are still used in some classic or heavy-duty vehicles. They rely on a direct connection to the oil line, physically measuring pressure through a Bourdon tube that moves a needle on a gauge.

Electronic sensors, however, dominate modern vehicles. They use electrical signals to communicate with the ECU or digital dashboard. These sensors are more precise, respond faster, and integrate seamlessly with advanced diagnostic systems.

| Type | Mechanism | Accuracy | Maintenance | Common Use |

|---|---|---|---|---|

| Mechanical | Uses direct oil pressure | Moderate | Higher | Classic vehicles |

| Electronic | Uses electrical signals | High | Low | Modern vehicles |

While electronic sensors are more convenient and accurate, they also rely heavily on the integrity of electrical systems. Regular checks ensure they continue functioning properly.

Oil Pressure Sensor and Warning Lights

One of the main interactions drivers have with the oil pressure sensor is through the dashboard warning light. When that red oil can icon illuminates, it’s the sensor signaling potential trouble. However, not every instance means a serious problem — sometimes, it’s just the sensor acting up.

If the warning light flickers briefly during start-up, it’s often normal. But if it stays on while driving, it’s crucial to investigate immediately. The oil pressure sensor may have detected genuinely low pressure, or it might be sending a false alarm due to a wiring or calibration issue. Ignoring it is never advisable; even if it turns out to be a false reading, it’s better to confirm.

A functioning oil pressure sensor ensures that you receive accurate alerts when needed. This early notification system can make the difference between a quick fix and a major engine rebuild.

Troubleshooting Oil Pressure Sensor Issues

When troubleshooting an oil pressure sensor, start with the basics — check oil levels and condition first. Many times, the issue isn’t the sensor itself but dirty or insufficient oil. If that’s not the cause, inspect the wiring and connectors for any visible signs of wear.

Next, use a multimeter to check the sensor’s output signal. A fluctuating or unstable reading could indicate an internal failure. Some vehicles require the use of a diagnostic tool to reset the oil pressure warning system after repairs. Ensuring that all connections are secure and clean is vital for proper readings.

If all else fails, replacing the sensor is often the simplest and most reliable solution. Fortunately, oil pressure sensors are affordable and widely available, making them an easy fix for an otherwise potentially serious issue.

Quotes About Oil Pressure Sensor Importance

“A small sensor can save a big engine.”

“Your oil pressure sensor doesn’t just measure — it protects.”

“Ignore your oil light today, buy a new engine tomorrow.”

These quotes highlight the crucial but often-overlooked role of this component. Paying attention to its warnings means respecting your vehicle’s health.

Frequently Asked Questions

What does an oil pressure sensor do?

An oil pressure sensor measures the oil pressure in your vehicle’s engine and sends that data to your dashboard or computer system. It alerts you when pressure drops too low to prevent engine damage.

How do I know if my oil pressure sensor is bad?

Common signs include flickering warning lights, inaccurate pressure readings, or no response from the oil pressure gauge. If these occur, have the sensor tested or replaced.

Can I drive with a bad oil pressure sensor?

Technically yes, but it’s risky. Without a functioning sensor, you won’t know if your engine oil pressure is dangerously low. It’s best to replace the faulty sensor immediately.

Where is the oil pressure sensor located?

The sensor is typically located near the oil filter or on the engine block. Its exact position can vary depending on your vehicle’s make and model.

How much does it cost to replace an oil pressure sensor?

On average, replacement costs range from $50 to $200, including labor. The sensor itself is usually inexpensive; most of the cost comes from labor time.

Conclusion

The oil pressure sensor might be a small, inexpensive part, but it plays a monumental role in keeping your engine healthy. By continuously monitoring oil flow and pressure, it prevents unseen problems from escalating into costly disasters. Regular maintenance, timely diagnosis, and replacement when needed ensure your vehicle runs efficiently for years.

Understanding how your oil pressure sensor works empowers you to make smarter decisions about car care. After all, this little device could be the silent hero that saves your engine from serious damage.